Bildnachweis: mewaji – stock.adobe.com, Acies Bio.

Acies Bio works on the optimisation of different microorganisms to create new components, processes and products for a bio-based future. One of the unique aspects of Acies Bio is that they have a huge amount of knowledge about the versatility of these microorganisms and the feedstocks needed to cultivate them. By Urs Moesenfechtel

But the common ways of cultivation and following fermentation processes of microorganisms are mostly based on glucose, which is also a food source. Therefore, they are looking for other solutions.

Circular bioeconomy at its best

Acies Bio is mainly known for its partnership with the German feed producer EW nutrition GmbH. Within their Whey2Value project, Acies Bio developed non-GMO microorganisms and a technology that allows the conversion of waste whey into vitamin B12. Other available commercial products use highly toxic cyanide during the isolation process of this vitamin. EW Nutrition sells vitamin B12-enriched biomass as an animal feed premix in more than 90 countries. Whey2Value has the potential to have a disruptive impact on the processing of this waste stream and could make it more efficient and sustainable. The production of valuable products from waste is a perfect example of a profitable circular bioeconomy. However, according to Martin Kavscek. Senior R&D Manager at Acies Bio, “there is a lot of waste whey in the market, but when you think about industrial production of biochemicals, it is still limited. And we urgently need to step out of the food chain. That’s why we are looking for alternative feedstocks.”

Using alternative feedstocks

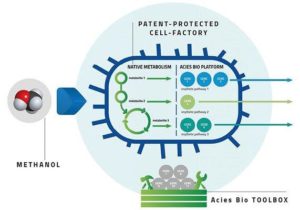

To solve this problem, Acies Bio recently came up with the “OneCarbionBio” platform that employs a synthetic biology engineering technique to transform methanol into bioproducts such as sustainable chemicals, biodegradable plastics, and ingredients for food or feed. The methanol is synthesised from waste CO2, which provides molecules (monomers) at a high level of concentration. Independently genetic tools, patented chassis strains, high cell-density fermentation techniques and process innovations have led to nearly twenty product inventions so far. But Acies Bio does not aim to be the final producer of these products; they want to sell the technology itself. To achieve this, they scaled up their processes to TRL6 to prove their functionality at the kilogram scale. As a next step, they want to team up with different companies in the chemical, agriculture and food industries who already have access to the market. “The best feature of the platform is that the processes can be adapted very quickly to the desired end product,” Kavscek says. Currently, they are negotiating a joint investment for the production of amino acids. The goal: Acies Bio provides the process expertise, the partner provides the financing and speeds up the development of this product and many others. Acies Bio ultimately generates its revenue from royalties on these products.

Growing strong, living long

Acies Bio was established 15 years ago by four scientists and is now a team of 60. In December 2020, they started to expand their pilot scale facility to 30 m3 total volume and a downstream processing facility expanded with several new unit operations. This enables Acies Bio to better serve a broader range of microbial biotechnology projects and provide its partners with more efficient scale-up processes regardless of the final product. The expanded facility will be used primarily to produce sustainable fertilisers for iron supply solutions based on natural, biodegradable chelators. Since May 2021 the facility has been fully operational. Acies Bio thus continues to pursue a clear growth course – with financial support from the EU in the scope of the SUSFERT project, a BBI-JU project co-founded by the EU Commission and its own investments, mainly derived from patents and licences.

Short profile of Acies Bio

Founded: 2006

Industry: Chemical industry

Number of employees: 60

Internet: www.aciesbio.com

Autor/Autorin

Urs Moesenfechtel, M.A., ist seit 2021 Redaktionsleiter der GoingPublic Media AG - Plattform Life Sciences und für die Themenfelder Biotechnologie und Bioökonomie zuständig. Zuvor war er u.a. als Wissenschaftsredakteur für mehrere Forschungseinrichtungen tätig.