Bildnachweis: TreaTeach, Source: TreaTech AG, Photo: © M. Fischer – Paul Scherrer Institute 2020, Photo: © TreaTech AG.

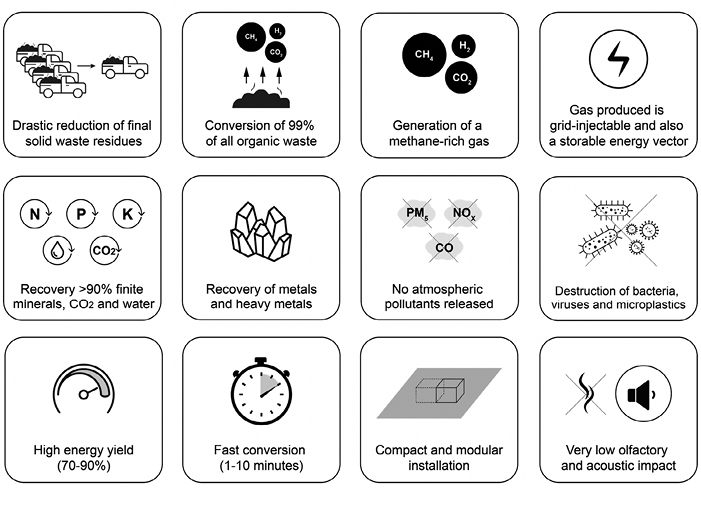

TreaTech has developed a system that converts 99% of all organic waste such as sewage sludge into reusable products such as fertiliser, renewable gas and clean water.

For a long time, sewage sludge from wastewater treatment plants was disposed of directly as fertiliser. Although sewage sludge contains plant nutrients such as phosphorus and nitrogen, it also contains a whole range of pollutants and pathogens from industry, commerce, and private households. Due to these major concerns, Switzerland banned the use of sewage sludge in agriculture back in 2006, and incineration became the disposal reference.

Capturing the true value of waste products

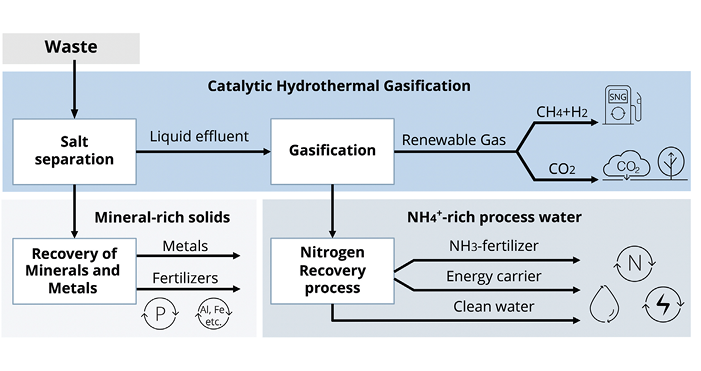

However, this ban also means that valuable sewage sludge components such as water or phosphorus are lost while incinerating. Given that this problem had been foreseeable for some time, engineers at the École Polytechnique Fédérale de Lausanne (EPFL) began designing a corresponding system back in 2015, which has now given rise to the spin-off TreaTech. Thanks to a technology developed at the Paul Scherrer Institute, the TreaTech system can also produce biogas, salts and minerals from wastewater. This is possible with the help of hydrothermal gasification (HTG). “Our system can dispose sludge directly from wastewater treatment plants without the need for drying or other pre-treatment,” says Fréderic Juillard, CEO and founder of TreaTech.

A circular way of processing waste

By converting 99% of the organic carbon in any waste product into pollutant-free gas, it is possible to power the entire waste treatment process in a circular way and to replace fossil fuels. This circular economy is further supported by recovering CO2, clean water and minerals that can be transformed into fertiliser. The water can then also be reused on or off site, creating a closed-loop waste treatment solution.

Tried and tested

According to the company, the technology has been validated with more than 30 different industrial feedstocks including residues from monomer production, plastic, paint, coffee ground or sugar residue. The technology was also validated with digested and undigested sewage sludge from several Waste Water Treatment Plants (WWTPs) in Switzerland and France.

Upcoming steps

The company’s current and anticipated production volumes are focused on a range of 100-200 kg/h per unit. A significant milestone in 2024 will be the installation of an inaugural industrial pilot at a client’s location in Switzerland. Building on this foundation, they are ambitiously planning the rollout of an industrial-scale unit in 2025 which can handle 3 to 4 tonnes per hour. As part of their commitment to advancement, they are actively engaged in ongoing innovation efforts, which center around the continuous development of catalysts with selectivity to either hydrogen (H2) or methane, adapting to specific operational requirements as needed. The TreaTech technology can already transforms 99% of the organic carbon from any wastewater into pollutant- free, methane-rich renewable gas (up to 70 vol.% vs. industry average of 40 vol.%) suitable for the grid network. The company’s initial focus is directed towards industrial clients, allowing them to fine-tune and optimise their technology for the customer’s specific needs.

Every innovation needs a solid foundation

“We see ourselves as a technology developer that will license its technology to Engineering-Procurement-Construction (EPC) partners or provide direct services to end-customers,” says Juillard. “Looking further ahead, our strategic roadmap includes the implementation of our technology for the municipal sector, scheduled for the year 2027.” To reach this goal, they recently closed a Series A financing round of over CHF 9 million in July 2023. It was led by Engie New Venture and Montrose Environmental Group with the support of the EIC Fund, Sipchem, CMA CGM Fund for Energies, and Holdigaz. Funds raised since TreaTech’s inception now total CHF 15 million, including initial seeding from PM Equity Partner, Swiss Federal Office of Energy, Swiss Federal Office of Environment, Fondation pour le Climat, Gebert Rüf Stiftung, Bridge SNF, and Innosuisse among others. A Series B over CHF 20 to 30 million CHF) is planned for 2025.

SHORT PROFILE OF TREATECH AG

Foundation: 2015

Sector: CleanTech/Waste-to-energy

Location: Lonay (Switzerland)

Employees: 12 FTE

Internet: https://trea-tech.com

powered by:

This article was published in the current Plattform Life Sciences issue „Circular Bioeconomy 4_23“, which you can view as an e-magazine via the following link: https://www.goingpublic.de/wp-content/uploads/epaper/epaper-Life-Sciences-4-2023/#46

Autor/Autorin

Urs Moesenfechtel, M.A., ist seit 2021 Redaktionsleiter der GoingPublic Media AG - Plattform Life Sciences und für die Themenfelder Biotechnologie und Bioökonomie zuständig. Zuvor war er u.a. als Wissenschaftsredakteur für mehrere Forschungseinrichtungen tätig.